- Operating Temp: EPDM : -40°C to max. +90°C, PVC : -20°C to max. +80°C

- Nominal voltage: 1100 V

- Test voltage: 3000 V

- Min. bending radius: 6 x cable diameter

- Flame propagation: Flame retardant test as per IEC 60332-1

Rubber Drincable Structure:

generally conforms to, CENELEC HD 22.1.S2, DIN VDE 0282 PART 810, IEC 245, CEI 20-19 & BS 6007, BS 6899

Copper:

EC flexible copper generally conforms to IEC 60228, DIN VDE 0295,IS 8131

Insulation:

Water resistant EPDM base rubber

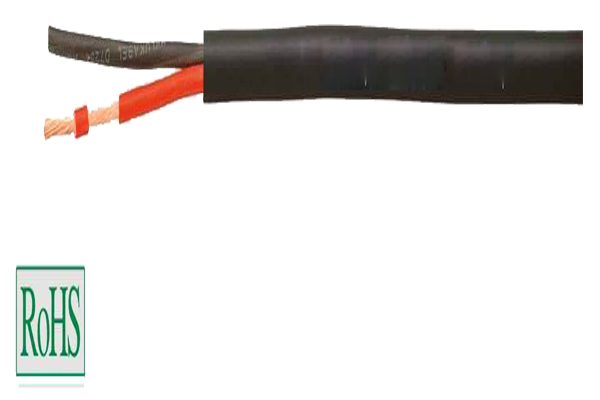

Outer Sheath:

Special Rubber sheathed Lead free compound

PVC Drincable Structure:

generally conforms to HD 21, UL-83,IEC 60227, BS 6500, DIN VDE 0281, IS 694

Copper:

EC flexible copper generally conforms to IEC 60228, DIN VDE 0295,IS 8131

Insulation:

Lead Free PVC

Outer Sheath:

Lead Free PVC

Flat – Drincable

Jainam pump cables designed for use as submersible pump, deep well and motor lead cable.

Jainam extra flexible submersible pump cables are use for submersible pumps, underwater lighting and floating switches etc. up to the depth of 500 m and water temperature up to +75 °C. These cables are ideal for outer installations in dry, moist and wet environments but however not suitable for explosive areas.

Standard length cable packing:

Coils 100, 200,300 and 500, 1000m. in wooden reels

A submersible Pump cable is a specialized product to be used for submersible pumps in a deep well. The area of installation is physically restrictive, and the environment is very hostile. Jainam is designed and manufactured keeping in mind these factors to achieve the highest possible degree of reliability.

| Cores colour: Core Identification | ||

| Color coding | As per IEC 60227 | As per IS 694 |

| 3 Core | Black, Light Blue and Brown | Red, Yellow and Blue |

| 4 Core | Black, Light Blue, Brown, Yellow with Green Line/ Green with Yellow Line | Red , Yellow, Blue, Green / Black |